Researchers at UT Dallas have discovered the root cause of lithium nickel oxide (LiNiO₂) battery degradation and developed a structural reinforcement technique that could lead to longer-lasting lithium-ion batteries for commercial use.

LiNiO₂ is a promising candidate for next-generation lithium-ion batteries due to its potential for extended lifespans. However, its commercialization has been hindered by degradation that occurs after numerous charging cycles.

The team at the University of Texas at Dallas has pinpointed the source of this degradation and is currently testing a solution that could eliminate a significant barrier to its broader application. Their findings were recently published in Advanced Energy Materials.

The researchers aim to initially produce LiNiO₂ batteries in their lab and ultimately collaborate with industry partners to bring this technology to market.

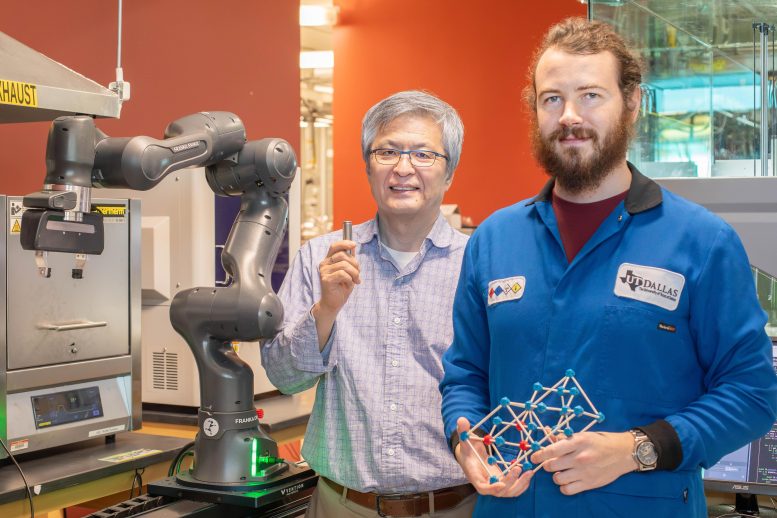

“The degradation of LiNiO₂-based batteries has been an ongoing issue for decades, yet its underlying cause has remained elusive,” explained Dr. Kyeongjae Cho, professor of materials science and engineering in the Erik Jonsson School of Engineering and Computer Science, and director of the Batteries and Energy to Advance Commercialization and National Security (BEACONS) program. “Now that we have clarified the reasons behind this degradation, we are developing a solution to enable the use of this technology for longer-lasting batteries in various products, including smartphones and electric vehicles.”

This research is part of UTD’s BEACONS initiative, which was launched in 2023 with a $30 million grant from the Department of Defense. The mission of BEACONS is to innovate and commercialize new battery technologies and manufacturing processes, enhance domestic availability of critical raw materials, and train skilled workers for the growing battery energy storage sector.

Computational Analysis of Battery Degradation

To investigate why LiNiO₂ batteries fail during the final charging phase, UT Dallas researchers conducted computational modeling. This study involved examining the chemical reactions and electron redistribution through the materials at the atomic level.

In lithium-ion batteries, electrical current flows from a positive electrode known as the cathode to a negative electrode, or anode, which is typically composed of carbon graphite that retains lithium at a higher potential.

During discharge, lithium ions move back to the cathode via the electrolyte, sending electrons back to the lithium-containing cathode through an electrochemical reaction that generates electricity. Cathodes are usually made from a blend of materials, including cobalt, a rare resource that scientists seek to replace with alternatives like lithium nickel oxide.

The UT Dallas team discovered that a chemical reaction involving oxygen atoms in LiNiO₂ leads to material instability and cracking. To address this issue, they formulated a theoretical solution that strengthens the material by introducing a positively charged ion, or cation, which alters the material’s properties and creates “pillars” to reinforce the cathode.

Matthew Bergschneider, a doctoral student in materials science and engineering and the study’s first author, is establishing a robotics-based lab to manufacture battery prototypes and explore high-throughput synthesis processes for the designed pillared LiNiO₂ cathodes. The robotic features will aid in synthesizing, evaluating, and characterizing the materials.

“We will begin with a small batch and refine our processes,” said Bergschneider, a Eugene McDermott Graduate Fellow. “Then, we plan to scale up material synthesis and produce hundreds of batteries per week at the BEACONS facility. Each step brings us closer to commercialization.”

Reference: “Mechanical Degradation by Anion Redox in LiNiO₂ Countered via Pillaring” by Matthew Bergschneider, Fantai Kong, Patrick Conlin, Taesoon Hwang, Seok-Gwang Doo, and Kyeongjae Cho, December 10, 2024, Advanced Energy Materials.